Laser Cutting Equipment Things To Know Before You Get This

Laser Cutting Equipment Things To Know Before You Get This

Blog Article

With regards to modern day producing, the precision and effectiveness of laser slicing technological innovation are genuinely match-modifying. Laser chopping machines have revolutionized industries by giving a method of chopping products with unparalleled precision. If you’ve ever marveled within the intricate patterns on metallic or questioned how sophisticated shapes are produced so seamlessly, it’s typically the get the job done of the industrial laser reducing machine.

Enable’s get started with the basics: a laser cutter is actually a Instrument that utilizes a laser beam to chop materials. This beam is extremely centered and generates large temperatures to soften or vaporize the material, producing precise cuts. Unlike traditional procedures, which might use mechanical blades, a laser cutter offers a level of precision that is almost unmatched. Imagine endeavoring to carve a fragile pattern with a hammer—clearly, a laser cutter is a great deal additional refined!

Industrial laser reducing requires this technological know-how to another amount, supplying methods for giant-scale functions. These machines are crafted to handle significant components and higher production volumes, guaranteeing that even the most demanding initiatives are accomplished with superior performance. Think of it because the difference between utilizing a precision knife for fragile paper crafts and a strong observed for reducing by means of thick Wooden.

Some Known Details About Industrial Laser Cutting

On the globe of CNC laser chopping, the “CNC” stands for Computer Numerical Handle. This technological innovation permits automatic and very exact cuts by pursuing electronic layouts. If you’ve at any time used a computer to attract and then noticed that drawing arrive at lifetime, CNC laser slicing is effective in an identical way, translating digital layouts into physical cuts. It’s like aquiring a Digital designer Along with the precision of a laser.

On the globe of CNC laser chopping, the “CNC” stands for Computer Numerical Handle. This technological innovation permits automatic and very exact cuts by pursuing electronic layouts. If you’ve at any time used a computer to attract and then noticed that drawing arrive at lifetime, CNC laser slicing is effective in an identical way, translating digital layouts into physical cuts. It’s like aquiring a Digital designer Along with the precision of a laser.A Biased View of Cnc Laser Cutting

Precision laser chopping is not pretty much making cuts; it’s about building them appropriate each and every time. The laser might be adjusted to obtain diverse depths and widths, making sure that every Reduce is strictly the place it really should be. This is crucial for apps where by even a slight deviation may lead to sizeable concerns. Imagine it for a surgeon’s scalpel, the place precision is not merely vital but Unquestionably important.

Precision laser chopping is not pretty much making cuts; it’s about building them appropriate each and every time. The laser might be adjusted to obtain diverse depths and widths, making sure that every Reduce is strictly the place it really should be. This is crucial for apps where by even a slight deviation may lead to sizeable concerns. Imagine it for a surgeon’s scalpel, the place precision is not merely vital but Unquestionably important.Laser reducing gear comes in numerous varieties, Every customized to precise wants. No matter if you need a little desktop product for hobby initiatives or a huge industrial equipment for manufacturing unit use, there’s a laser cutting Option in existence for you personally. These machines range in ability, speed, and capabilities, so it’s essential to pick the ideal a person for your particular software.

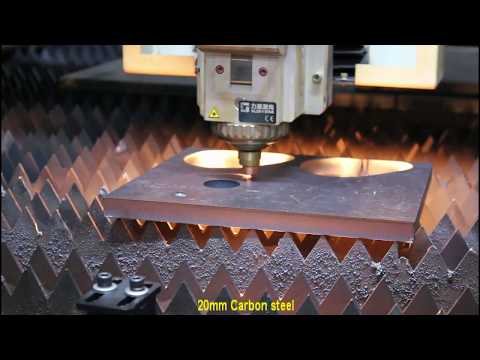

Sheet metal laser cutters can be a Specific classification of laser chopping equipment intended especially for reducing steel sheets. They are broadly used in industries ranging from automotive to aerospace because of their capacity to handle metal with precision and pace. Photo a sheet of metallic like a blank canvas, and the laser cutter since the artist who makes elaborate and beautiful designs with incredible accuracy.

Laser chopping products and services are Yet another important aspect of this engineering. Not everyone requirements to speculate in their unique laser reducing device, particularly if they only want occasional cuts or lack the Area for this kind of gear. A lot of firms supply laser reducing services in which you can ship your designs and possess them cut with large precision. It’s like outsourcing your artwork to a talented Experienced.

Laser reducing programs integrate different components to deliver the specified results. From your laser source on the cutting bed, along with the Manage software program, each and every part of the method will work alongside one another to be sure a flawless operation. It’s a get the details little just like a symphony orchestra, where by Each individual musician has a certain job, and only by Functioning collectively do they develop a harmonious functionality.

When it comes to laser chopping engineering, the evolution has been fast and extraordinary. Initially utilized mainly for reducing metals, these devices now tackle a variety of supplies which include plastics, Wooden, and in many cases fabrics. This versatility can make laser cutting technologies a valuable Instrument in a great number of industries. Visualize possessing a Swiss Army knife that may tackle nearly any materials—That is what modern-day laser reducing technological know-how delivers.

The precision of laser reducing machines is really remarkable. They're able to Minimize resources to in microns with the meant style and design, guaranteeing that even essentially the most intricate facts are preserved. This amount of precision is especially useful in industries where by precise measurements are essential. Think about it as being the distinction between a tailor-made accommodate and off-the-rack garments—the healthy is simply fantastic each time.

The Basic Principles Of Cnc Laser Cutting

Yet another benefit of laser cutting technologies is its efficiency. Not like traditional cutting techniques That may need various techniques or applications, laser cutting frequently completes the task in a single go. This don't just hurries up manufacturing but additionally minimizes product squander. It’s like having a substantial-pace coach that will get you towards your vacation spot rapidly and efficiently with no needless stops.From the context of industrial purposes, the robustness of laser slicing equipment is important. These machines are developed to endure the demands of constant Procedure, usually jogging 24/seven in large-volume settings. Their longevity ensures regular performance and dependability, which can be important for retaining manufacturing schedules. It’s like aquiring a weighty-responsibility truck that reliably delivers products working day just after working day.

One of the exceptional components of laser cutting is its capacity to create thoroughly clean and precise edges. This lowers the need for post-processing, including sanding or ending, which may be time-consuming and costly. The result can be a smooth, concluded item That always requires nominal supplemental perform. Picture ending a craft challenge without glue spills or tough edges—it’s that clean up!